Last Updated:

December 24, 2010

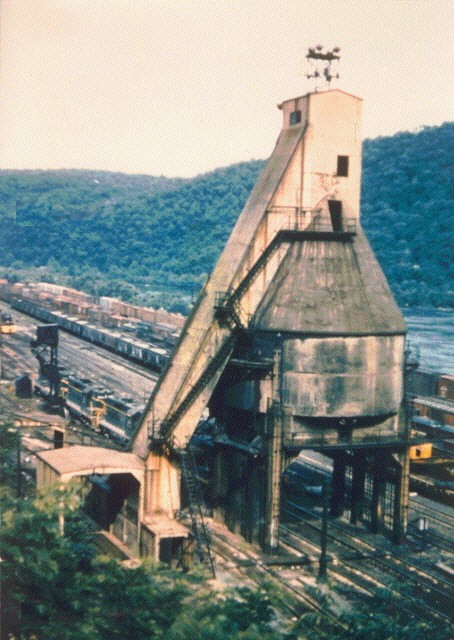

800

Ton

Fairbanks Morse Coal Docks

The Chesapeake & Ohio began extensive work

to modernize its physical plant in the middle and late 1920's. That effort led

to the mighty T-1 2-10-4 of 1930 and the many concrete coaling stations which

still dot the C & O although age and company efforts to clear the property of

taxable obsolete structures is beginning to make inroads. This article will

deal with only the Fulton Yard, Richmond, Virginia,

Stevens Yard, in

Kentucky (across from Cincinnati), and Hinton, West Virginia. All three yards

were redesigned in the late 1920's and very similar (if not identical)

equipment and structures were installed.

The most prominent feature of the three yards was of course the 800 ton

Fairbanks, Morse & Company coaling docks which replaced an earlier wood

ramp-style dock of 1890's vintage at Hinton and a wood elevator at

Fulton. The design of all three was

virtually the same with only minor changes. The most oblivious change was at

Fulton Yard where the skip hoist shaft was straight and not bent as at Hinton

and Stevens. The straight shaft design and wider space between the coaling

track and the fuel supply track also resulted in a different design for the

hoist house which contained the electric motors for the crusher and two skip

hoists. The crusher motor was located in the hoist house and powered the

crusher in the pit through a chain drive linkage.

The two skip hoist motors

directly powered winches which controlled cables which exited through the top

of the hoist house to cable sheaves located in the top of the coal dock

monitor. All three motors were air cooled with a air intake and exhaust

penetrating the roof or sides of the hoist house. The only other motor in the

coal dock was located in the monitor to shake the sorting grates which

separated the lump coal for "hand stampers" from stoker coal. It was also air

cooled and the air intake and exhaust were evidenced by the two approximately

8" diameter holes just below the top of the truncated cone and above the sand

bunkers.

The two skip

hoists were capable of elevating over 500 tons of coal per eight hour shift

assuming the weather was not so cold that the coal had frozen in the hoppers

which the laborers were dumping in the pit. At Hinton up to four coal dock

laborers worked the pit and two watered, coaled and sanded the engines. The

two working on fueling the engines would alternate the job of "engineer" and

laborer. In very cold weather the laborers built fires on steel plates beside

the hoppers on the fuel supply track to begin thawing the coal and then used

picks and shovels to break up the load. In the Spring, Summer and Fall the

laborers used hoses to wash the coal from the cars and keep down the dust.

</="font-size: 11pt; color: black"> In addition, the coal

docks each had two 10 ton dry sand bunkers to supply the sand boxes of

refueling engines. At Hinton in 1946 the capacity of each sand bunker was

increased by removing a part of the concrete top of each sand bunker and

adding a steel addition which increased each bunker capacity approximately 6

tons to 16 tons. The necessity for the addition is easily understood if one

takes into consideration the 8 ton capacity of the two sand boxes on the H-8

2-6-6-6's. The catwalk between the two sand bunkers was added in the 1930's

and the catwalk on the cone of the coal dock at Hinton was probably added in

1946.

Although very

massive (the eight legs of each coal dock are 3' x 2') the walls of the coal

dock and sand bunker were only 6" thick reinforced concrete and the hoist

house walls only 5" thick. Internally the Hinton and Fulton coal docks were

identical with a 200 ton lump coal bin and a 600 ton stoker coal bin. A total

of 8 coaling chutes were required to coal all four tracks from each bin. The

200 ton lump coal bin was located next to the sand bunkers and coaled all four

tracks. The 600 ton bin coaled the two center tracks from the center bay of

the coal dock and the two outside tracks from the two coaling chutes on the

opposite end from the sand bunkers. Therefore depending on whether the engine

was a

2-8-0 or 2-6-6-6, spotting

the engine for the correct type of coal was required. The coal dock at Stevens

had three internal bins - two 200 ton bins and a 400 ton bin in the center. As

a result the Stevens coal dock had a total of 12 coaling chutes so that each

bin could coal all four tracks. The reason for the difference is not known,

but may have been related to a perceived need for additional lump coal storage

due to locomotive types in the

Cincinnati area. A few notes on the drawings

are in order. The Stevens and

Fulton drawings are based upon my

measurements and photographs of the Hinton coal dock and the few Fairbanks

Morse & Company drawings which have turned up in COHS files. Therefore some of

the details have been omitted or may be incorrect depending on the limited

number of photographs of Fulton and Stevens I have had the opportunity to use.

The window show at the top of the cone is based upon the "Proposed coaling

station for Hinton" drawings which turned up in COHS files. The "window" at

Hinton is covered, but I do not know when or if the "windows" at Stevens and

Fulton were covered and therefore included the window in my drawings.

The elevated hoist house

at Stevens was added to the coal dock in 1948 probably to elevate the

electrical equipment above the flood plain. I happened to run across a drawing

bearing that date when helping to purge CSX engineering files at

Huntington circa 1986. I have not seen it

since, and the elevated hoist house and other drawings of Stevens are based

upon very limited photographic evidence. If anyone wishes to correct any

detail and provide the photographs or other evidence I will be most happy to

correct the detail. The Hinton drawings were almost complete before any

Fairbanks, Morse & Company drawings showed up in COHS files, but, so far, no

indicated dimension has been found to be off more than 3" and those have been

corrected. Should you want to add anything to the information provided, please

feel free. All the drawings are in CADD and are easily changed.

The Hinton coal dock drawings were

published in the September 1994 issue of Model Railroader at page 85 et

seq., and reference should be made to that magazine for additional details

and drawings.

Copyright 2003-2010 William E. Simonton, III